Discover the functions and hottest use circumstances of pc imaginative and prescient in manufacturing. We’ll cowl real-world functions of how manufacturing corporations can use deep studying and AI imaginative and prescient applied sciences to energy Pc Imaginative and prescient for inspection, office security, manufacturing facility automation, and high quality management.

On this article, we are going to present a state-of-the-art overview, new concepts for pc imaginative and prescient initiatives, real-world examples, and an trade outlook.

Purposes of Pc Imaginative and prescient In Manufacturing

- Utility #1: High quality Inspection and Management

- Utility #2: Optimizing Provide Chains

- Utility #3: Gear Monitoring and Predictive Upkeep

- Utility #4: Lean Manufacturing

- Utility #5: Security of Workforce and Gear

- Utility #6: Detecting Product Defects

- Utility #7: Actual-time Barcode Studying

- Utility #8: Automated Product Meeting

- Utility #9: Sustaining Packaging Requirements

- Utility #10: Pandemic Protecting Measures

The Platform To Construct Customized Pc Imaginative and prescient Techniques

Viso.ai supplies the main end-to-end Pc Imaginative and prescient Platform Viso Suite. Utilized by main producers and Fortune 500 corporations, the automated infrastructure allows groups to construct, deploy, and scale their pc imaginative and prescient functions. Get a demo on your group.

1. High quality Inspection with Pc Imaginative and prescient

One of the crucial vital makes use of of pc imaginative and prescient in manufacturing is for automating high quality inspection in the course of the manufacturing course of. Sustaining high quality requirements is of utmost significance within the subject of producing. Whereas one can do that manually by way of participating high quality management specialists, the probabilities of human error are fairly excessive and naturally restricted.

In consequence, a number of manufacturing companies are shifting in the direction of utilizing deep studying and pc imaginative and prescient for high quality management and inspection duties. Adopting such applied sciences ensures minimal human intervention whereas sustaining a excessive degree of accuracy within the course of. In addition to, these applied sciences are additionally economical, as they assist enhance operational effectivity and cut back labor prices.

Within the restricted atmosphere of a producing plant, pc imaginative and prescient can carry out many inspection duties quicker, extra precisely, and effectively than people. It turns into doable to examine each single half as an alternative of simply random samples.

Imaginative and prescient methods additionally apply a constant normal to beat variations throughout completely different human inspectors. Therefore, an automatic inspection can considerably enhance the effectivity of client product manufacturing. For instance, a scorching sauce maker checks the position of labels at a charge of over 1’000 per minute. Till now, machine imaginative and prescient inspection methods use strategies which might be custom-trained for specific inspection duties and are unable to be retrained. Nonetheless, machine learning-based approaches which might be deep learning-based are far more versatile.

2. Optimizing Provide Chains

Optimizing the provision chain course of is useful for manufacturing vegetation to cut back prices whereas enhancing buyer satisfaction. Whereas human intervention was mandatory for overseeing a number of elements of the provision chain course of previously, developments within the subject of pc imaginative and prescient have introduced a change on this side.

A number of manufacturing enterprises have turned to pc imaginative and prescient functions for duties like warehouse administration, managing inventories, and enhancing effectivity within the group. For instance, corporations like Amazon and Walmart are working to implement drone methods to observe warehouse inventories. For instance, real-time processing of digital camera streams is used to detect empty containers and optimize restocking.

3. Gear Monitoring and Predictive Upkeep

Manufacturing vegetation contain specialised tools for the manufacturing of products. With common use, these machines could present indicators of wear and tear and even malfunction, resulting in product defects and losses.

Using pc imaginative and prescient applied sciences is far more efficient than human observations in detecting such adjustments in manufacturing tools. Such applied sciences have been used to acknowledge defects in real-time, even in tiny machine elements. This makes it doable to find and restore the elements in time which might have in any other case precipitated the manufacturing course of to decelerate.

Deep studying is used for the fault analysis, leakage detection, and prognosis of commercial tools. Machine studying methods have been used to develop clever fault analysis methods. For instance, deep studying has been used to search out cracks in industrial parts similar to spherical tanks and strain vessels in oil and gasoline functions.

4. Digital Lean Manufacturing

Lean manufacturing is a manufacturing course of that makes an attempt to maximise productiveness whereas concurrently minimizing waste inside a producing operation. Business 4.0 applied sciences rework lean processes to advance the enterprise and supply a data-driven method to decision-making and automation with clever sensing applied sciences. Pc Imaginative and prescient is a key part of Business 4.0 applied sciences to digitize manufacturing vegetation.

Professional experiences from Deloitte estimate that the transformation from lean to digital lean will generate enchancment in EBITDA (earnings earlier than curiosity, taxes, depreciation, and amortization) of US$20 million yearly, lower prices by 15% per line per 12 months, and enhance normal tools effectiveness (OEE) by 11% yearly.

For instance, pc imaginative and prescient methods can acknowledge and monitor occasions and worker footfall (automated spaghetti diagram) to measure course of effectivity, present analytics to detect faulty tools and optimize workloads throughout the plant ground.

With the applying of pc imaginative and prescient in manufacturing, it has grow to be doable for a lot of enterprises to embrace this technique for enhancing their effectivity. Using pc imaginative and prescient functions in numerous phases of the manufacturing course of can assist cut back time, wastage, and prices whereas concurrently enhancing productiveness.

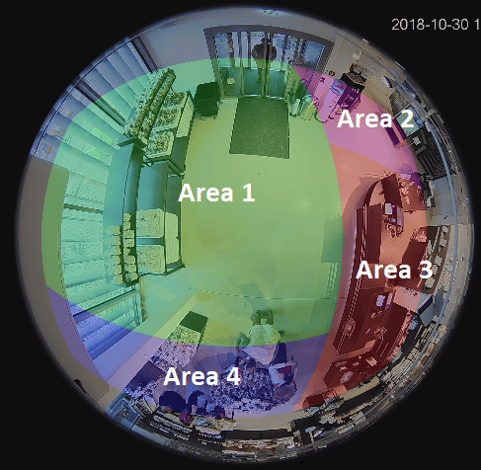

5. Security of Workforce and Gear

Staff in manufacturing enterprises typically undergo accidents whereas on the job. For employers, guaranteeing the protection of their workforce is of immense significance because it instantly impacts manufacturing.

Handbook monitoring processes are sometimes inadequate because the appointed individual could fail to successfully observe a number of screens without delay. And such errors could have monumental penalties for the workforce and the manufacturing agency.

Using pc imaginative and prescient applied sciences can successfully detect any points associated to security measures for the employees to create experiences in dashboards and ship notifications. It is usually doable to difficulty alerts mechanically in case there may be an accident in order that the administration can take the required measures instantly.

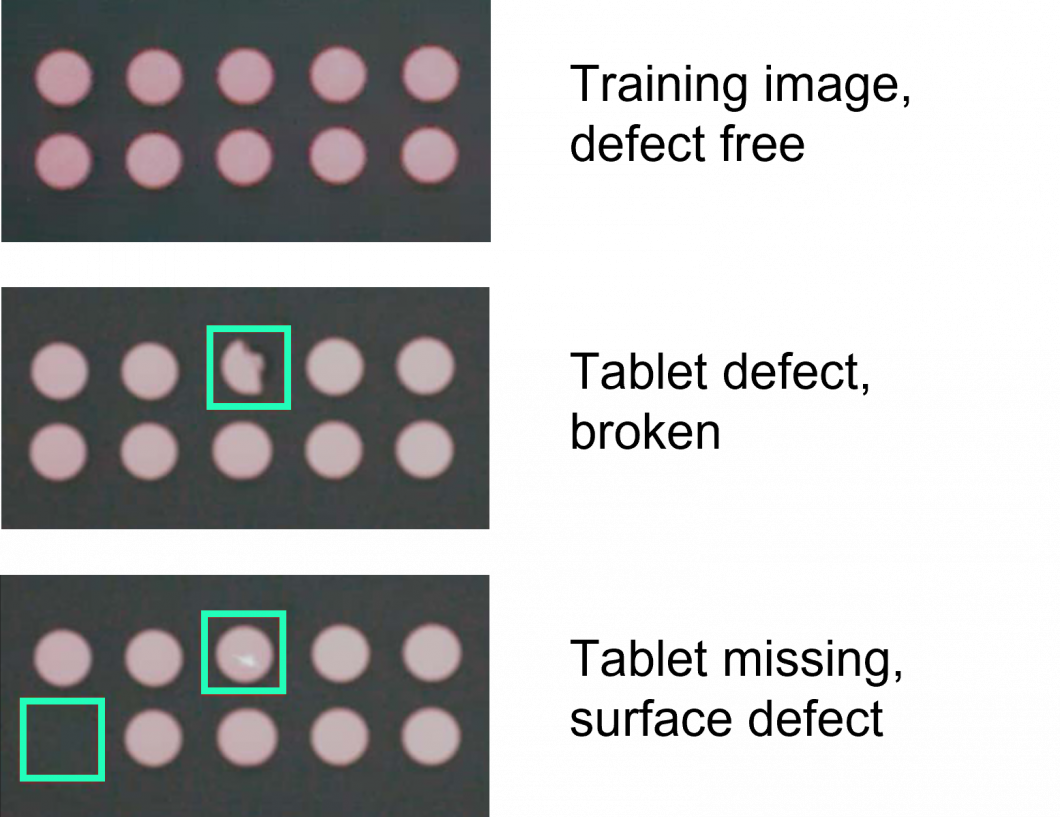

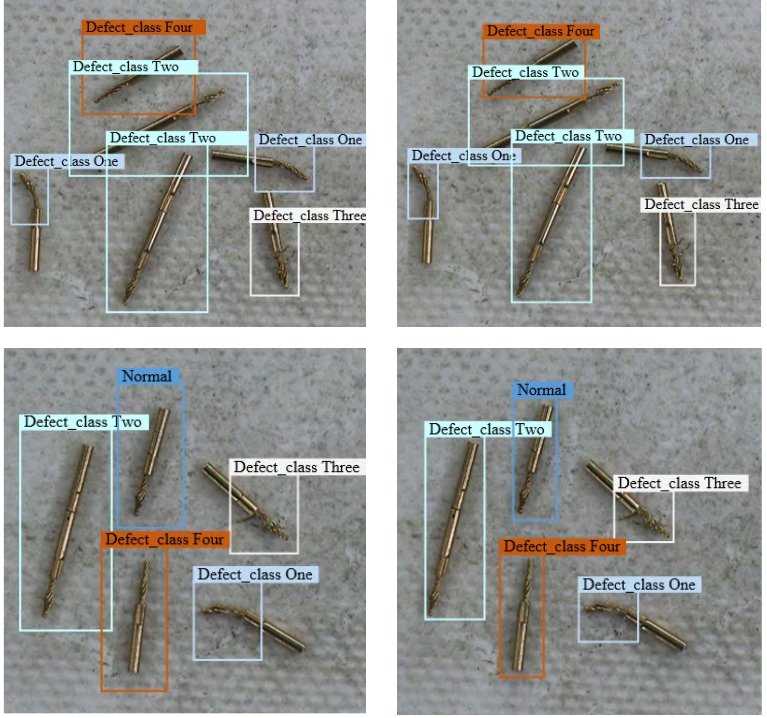

6. Detecting Product Defects

Using pc imaginative and prescient in manufacturing can assist detect faulty merchandise with exceptional ease. It may be powerful to manually determine smaller defects within the merchandise in the course of the manufacturing course of. Furthermore, the supply of an order containing a faulty product can’t solely result in elevated manufacturing prices but in addition buyer dissatisfaction.

Undoubtedly, this could have adverse penalties for the enterprise. Adopting a pc imaginative and prescient system for defect detection can prevent from these troubles by effectively monitoring the manufacturing course of to determine faulty items.

The instance exhibits defect detection with a real-time deep studying system. It was examined with completely different AI algorithms, together with YOLOv3 (32h coaching time), Quicker-RCNN, FPN, and a single shot detector (SSD) neural community (98% accuracy charge). In comparison with machine imaginative and prescient, deep studying is far more sturdy and versatile, making {hardware} comparably less expensive.

7. Actual-time Barcode Studying

In the present day, most merchandise include a barcode for simple identification functions. Manufacturing companies want to make sure that the merchandise have precisely printed barcodes earlier than dispatching them to the market.

Manually verifying every barcode is a time-consuming affair, to not point out the related prices of labor. Regardless of these handbook checks, errors are inevitable. Pc imaginative and prescient methods are a preferable different right here to acknowledge correct barcodes. It will probably confirm a number of barcodes in comparatively much less time with excessive effectiveness.

Such methods could be skilled to divert any product with defective or incorrect barcodes to the manufacturing division for evaluation.

8. Automated Product Meeting

Manufacturing companies all around the world are quickly transferring in the direction of pc vision-based methods to automate their product meeting course of. Together with guaranteeing correct assemblage of the product, the usage of pc imaginative and prescient makes the method a lot faster.

This know-how includes the era of a 3D mannequin design utilizing specialised software program based mostly on which the pc imaginative and prescient system executes the method of meeting. This course of is very related for manufacturing vegetation coping with small or delicate elements that can not be correctly managed by hand. Using pc imaginative and prescient methods can exactly monitor and full the meeting course of with minimal error.

9. Sustaining Packaging Requirements

Product packaging is of essential significance for manufacturing companies because it helps shield the merchandise from harm. To keep up their packaging requirements, manufacturing companies typically deploy pc vision-based methods.

Using such applied sciences is especially widespread in pharmaceutical pc imaginative and prescient functions, the place it’s important to depend the variety of items earlier than packaging. These producers want to take care of a specified variety of entire tablets or capsules per bottle with out fail. Pc imaginative and prescient helps in doing the duty with the required precision and automation.

Furthermore, the system could be skilled to verify for damages on the ultimate packaging and divert any product discovered missing on this side. One other use case is the inspection of incoming items to detect points early and mechanically doc potential insurance coverage circumstances.

10. COVID-19 Pandemic Protecting Measures

Because the COVID-19 pandemic hit the world in early 2020, it introduced a number of manufacturing actions to a halt. Even because the actions resumed, a number of manufacturing vegetation made social distancing and sporting masks necessary for employees’ security.

Pc imaginative and prescient functions are tremendously useful on this case, as they make it doable to successfully monitor the workforce to determine any violations of the Covid-19 protocol. As well as, the usage of such pc imaginative and prescient fashions in manufacturing vegetation will guarantee a secure working atmosphere throughout and even after the pandemic.

An instance utility is social distancing detection with pc imaginative and prescient, the place deep studying fashions detect folks and their distance. The beneath app was constructed with Viso Suite, utilizing an everyday Intel computing gadget with NVIDIA GPU and video enter from a community video digital camera.

One other utility to implement pandemic measures is automated masks management to detect unmasked folks effectively. Masks detection in factories is among the hottest new use circumstances for pc imaginative and prescient. To study extra about the usage of AI imaginative and prescient to fight COVID-19, learn our skilled information Pc Imaginative and prescient for Coronavirus Management in 2022.

Business Outlook

Pc Imaginative and prescient has a variety of functions in manufacturing, a lot of which have their origin in associated industries. For instance, individual detection and monitoring are already broadly utilized in Retail functions. Nonetheless, the effectivity beneficial properties of optimizing productions and automating security methods typically present larger worth in comparison with different use circumstances. We count on many extra functions to be broadly launched as deep studying know-how matures, making it doable to energy pc imaginative and prescient at scale.

New applied sciences similar to Edge AI make it doable to scale AI imaginative and prescient methods with deep studying in real-world functions. The rising new mega-trend is to transfer machine studying from the cloud to the sting to carry out on-device processing with computer systems related to cameras. Edge ML makes it doable to energy high-performance, sturdy, and personal pc imaginative and prescient functions.

What’s subsequent

If you’re all in favour of constructing and creating deep studying functions, try Viso Suite, the end-to-end platform to construct, deploy, and monitor pc imaginative and prescient functions in manufacturing.

Learn extra about associated matters.